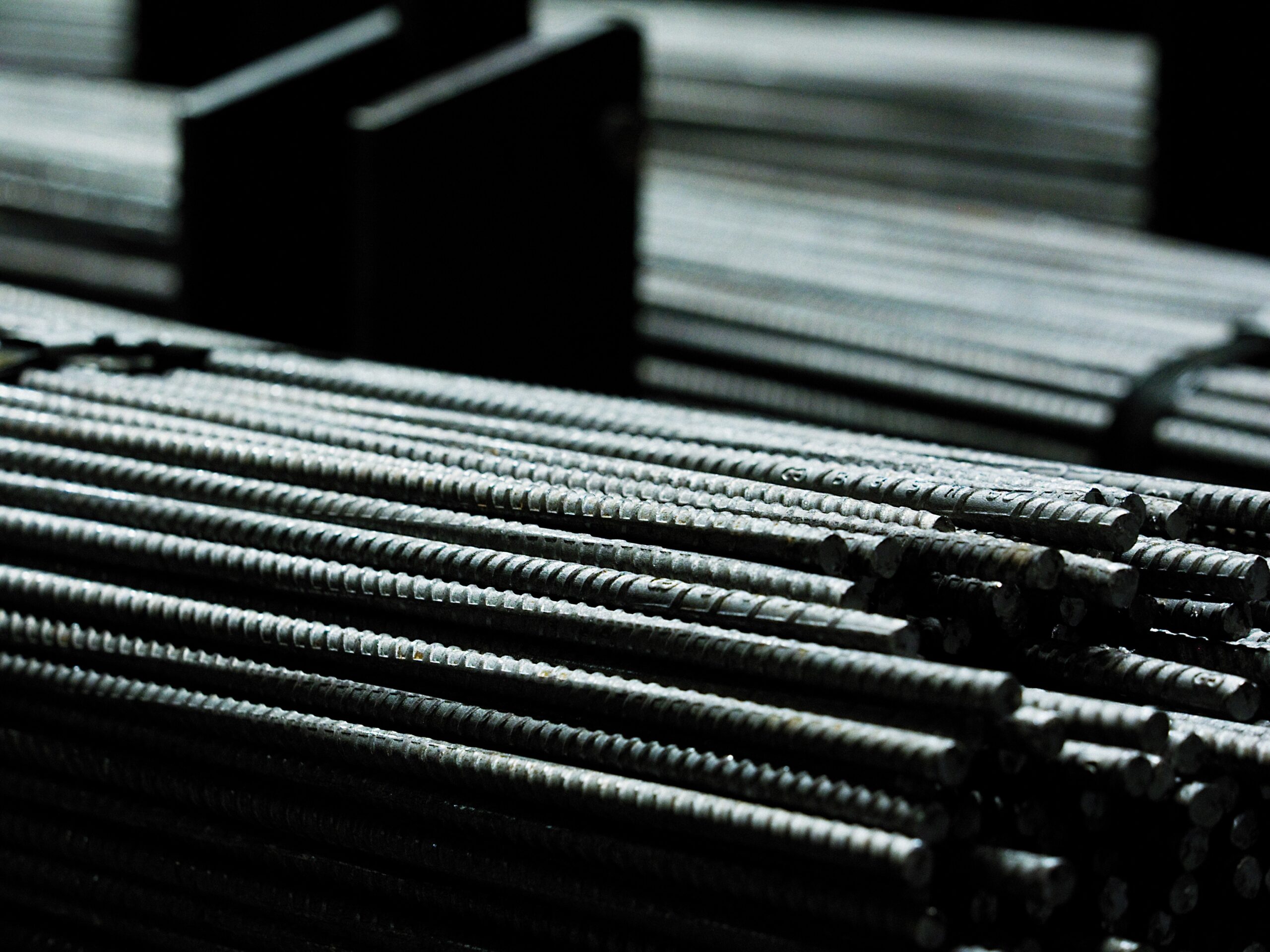

Types of Rebar and Their Uses

Across the construction and manufacturing industries, rebar is essential for providing tensile strength, preventing cracks, and enhancing stability in concrete structures. Westfield Steel offers a variety of rebar types to meet the diverse needs of your unique projects and applications.

-

CARBON STEEL REBAR

The most widely used type of reinforcing bar, carbon steel rebar, is known for its high tensile strength and outstanding affordability. With strength to prevent cracking or shifting and ensure a stable base for building foundations, roads, bridges, and structures of all sizes, carbon steel rebar is suitable for a broad range of applications.

-

EPOXY-COATED REBAR

This type of steel rebar features an additional protective epoxy coating to offer enhanced corrosion resistance. Epoxy-coated rebar is ideal for use in environments frequently exposed to moisture or chemicals, such as marine structures like docks, piers, wastewater treatment plants, and coastal construction projects.

-

GALVANIZED STEEL REBAR

Galvanized rebar undergoes a coating process with a layer of zinc, providing superior resistance to rust and corrosion beyond that of epoxy-coated rebar. This resistance makes galvanized rebar an excellent choice for marine environments, bridges spanning bodies of water, and other structures subject to harsh weather conditions.

-

STAINLESS STEEL REBAR

Known for exceptional durability and corrosion resistance, choose stainless steel rebar for projects requiring long projected lifespans and minimal maintenance. Stainless steel rebar is ideal for critical infrastructure in heavy-traffic areas or extreme environments.

No matter which type of rebar your construction or manufacturing project calls for, Westfield Steel offers custom rebar fabrication services to help meet

Get A Quote

Understanding the Critical Role of Rebar in Construction and Manufacturing

Rebar is a fundamental component in construction and industrial applications, playing a vital role in significantly enhancing the strength,resilience, and durability of concrete and masonry structures. From the foundations of buildings to the extensive and intricate networks of roads, bridges, and expansive infrastructure, rebar plays a critical role in ensuring long-term structural stability and safety, essential for the longevity of these constructions.

In more specialized and demanding applications, such as power plants, marine structures, and seismic-resistant buildings, rebar becomes even more critical. The right type of rebar, whether for withstanding the immense pressures of a coastal environment or the powerful forces of an earthquake, can make all the difference in a project’s ultimate success and structural integrity.

When selecting rebar, it is essential to consider and carefully evaluate factors like grade, size, coating, and compliance with stringent industry standards to ensure it meets your project’s specific and unique needs. These critical choices directly and significantly impact the construction’s overall structural integrity, longevity, and safety, ensuring the project’s success.

LEARN MORE: WHAT IS REBAR USED FOR?

The Impact of Custom Rebar Fabrication on Project Success

In construction and manufacturing, the precision and quality of materials play a pivotal role in determining the success and performance of a project. Rebar, while often unseen, is a critical component in reinforced concrete structures, contributing significantly to their strength and durability. However, not all rebar is created equal, and opting for custom rebar fabrication can have a profound impact on your project’s efficiency, cost-effectiveness, and overall quality.

Custom rebar fabrication involves tailoring rebar to meet specific project requirements, whether cutting to precise lengths, bending to fit unique architectural designs, or welding and coupling for enhanced stability. These value-added services streamline the construction process, reduce on-site labor and waste, and ensure that every piece of rebar meets stringent quality and safety standards.

By choosing a steel supplier that offers custom rebar fabrication, you can benefit from increased precision and quality control, significant time and cost savings, enhanced safety, and simplified project management. These advantages not only improve the efficiency of your construction operations but also contribute to the long-term success and integrity of your projects.

LEARN MORE: CUSTOM REBAR FABRICATION SUPPORTS CONSTRUCTION & MANUFACTURING SUCCESS