PRECISION FABRICATION: UNLOCKING THE FULL POTENTIAL OF STEEL PLATES

Steel plates are a foundational component in countless industrial, structural, and manufacturing applications. Their versatility is unmatched, but realizing steel plates’ full potential often depends on expert fabrication. High-precision welding, bending, and burning processes are essential for transforming raw steel plates into production-ready components. Whether your steel plates require high-strength welds, complex bends, or intricate cuts, the right techniques with appropriate steel plate types ensure superior results.

Steel Plate Welding: Strong, Reliable Bonds

Welding joins steel plates to create larger structures, reinforced components, and specialized assemblies. The process applies high heat to melt and fuse metal and requires certified experts to maintain proper heat control, electrode selection, and gas shielding to prevent porosity, cracking, or incomplete fusion.

Some of the top steel plate styles and grades well-suited for welding include:

ASTM A-516

This pressure vessel-grade steel allows for strong, defect-free welds even in high-pressure environments. Preheating and controlled cooling improve performance and reduce cracking risks.

Hot-Rolled ASTM A-36

Its low carbon content provides excellent weldability, and ASTM A-36 requires minimal preheating to offer smooth, consistent fusion across various welding processes.

ASTM A-572

Lightweight and high-strength A-572 welds effectively with low-hydrogen techniques for durable and high-performance welds in structural applications.

Steel Plate Bending: Precision in Every Curve

Bending reshapes steel plates without compromising structural integrity. The process is essential for fabricating cylindrical structures, with factors such as material thickness, bend radius, and applied force determining the success of a bend. Press brakes and roll bending machines ensure accurate deformation, allowing for angles, curves, and complex geometries while preserving material integrity.

Some of the top steel plate styles and grades for bending include:

ASTM A-516

With excellent formability and toughness, A-516 plates bend well for pressure vessels and industrial applications.

Hot-Rolled ASTM A-36

A-36 is highly malleable, making it an ideal choice for structural or machinery components requiring smooth, precise bends.

ASTM A-514

High-strength A-514 steel plates require preheating to prevent cracking, but the proper technique can deliver durable and precise bends for heavy equipment applications.

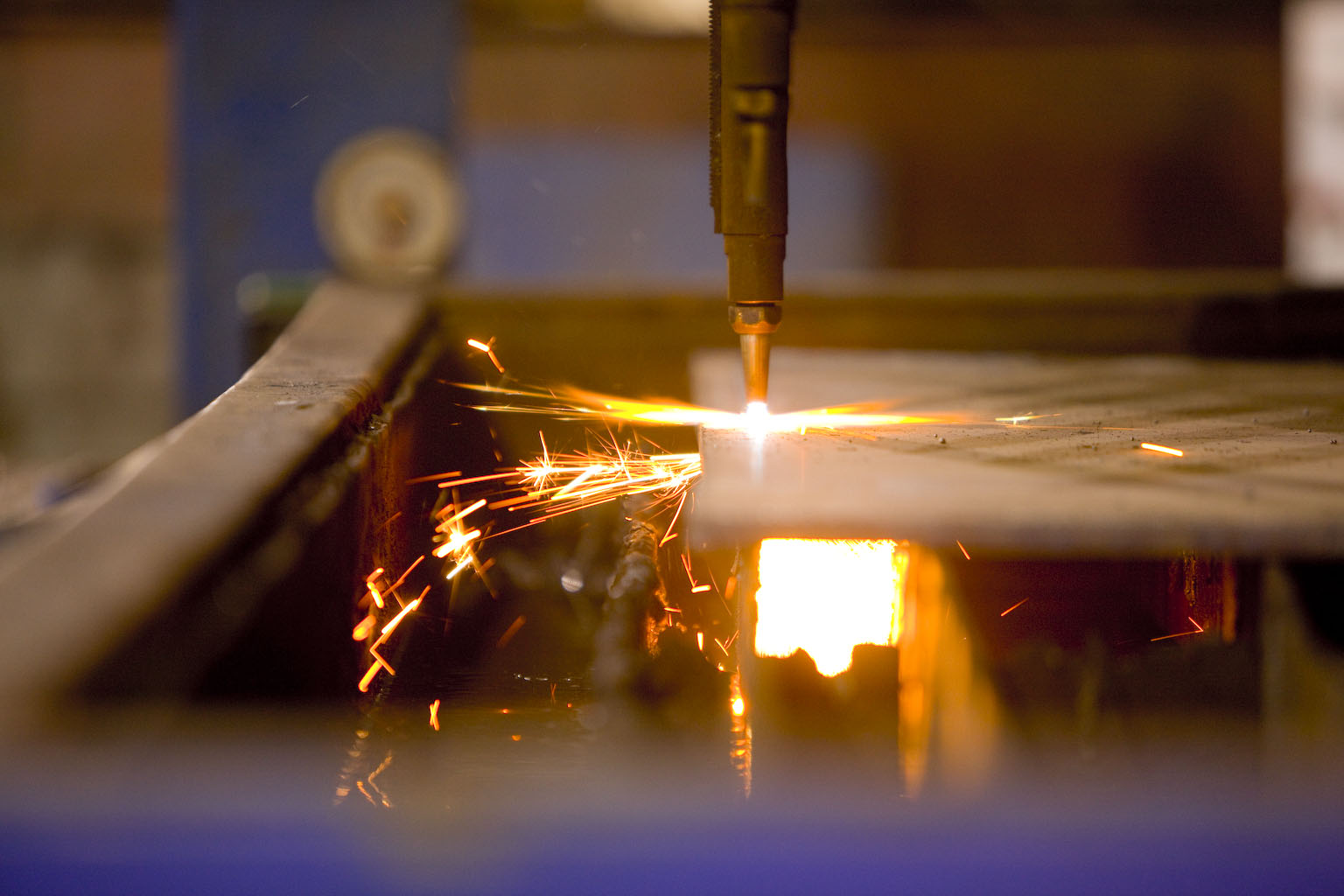

Steel Plate Burning: Cutting Steel Plates with Precision

Burning, or thermal cutting, efficiently separates and removes sections of steel plates with high accuracy. Burning processes vary based on steel plate thickness and composition. Oxy-fuel cutting works best for thick carbon steel plates, plasma cutting is ideal for medium-thickness plates requiring clean edges with minimal distortion, and laser cutting delivers extreme precision for thinner plates with intricate detailing.

Some of the top steel plate styles and grades for burning methods include:

Hot-Rolled ASTM A-36

Ideal for general-purpose cutting, A-36 cuts cleanly and precisely with minimal effort across various thermal cutting methods.

ASTM A-572

Its high strength makes A-572 reliable for burning processes with structural integrity, even in complex designs.

ASTM A-656

With excellent toughness and cutting stability, A-656 is well-suited for applications requiring strength and precision in thermal cutting.

Find Expert Fabrication Backed by Industry Knowledge

Fabrication requires more than just the right steel plate grades—it demands the right techniques, tools, and expertise. With proper material selection and precision fabrication, steel plates become durable, high-performing components for a wide range of applications.

LEARN MORE: OVERCOMING FABRICATION CHALLENGES OF ASTM A516 STEEL PLATES

WEATHERING STEEL PLATES: BUILT TO LAST, ENGINEERED FOR PERFORMANCE

Weathering steel plates combine enhanced strength and longevity with cost-efficiency for enduring harsh environments while requiring little maintenance. As they age, a protective oxide layer, known as a patina, forms naturally, shielding the weathering steel plates from further corrosion. Industries that demand durable, structurally sound materials rely on weathering steel to deliver lasting performance in the face of potentially punishing conditions.

ASTM A-588: A Durable and Resilient Weathering Steel

The most common weathering steel grades. ASTM A-588 is a high-strength, low-alloy steel plate grade that resists corrosion far better than standard carbon steel. Its superior atmospheric resistance makes it ideal for outdoor structures where reducing maintenance and material replacement costs is a priority. Engineers often select ASTM A-588 for bridges, buildings, and transportation infrastructure due to its ability to withstand constant exposure to the elements.

What Sets Weathering Steel Apart?

Built-In Corrosion Resistance

The naturally forming patina replaces the need for paint or protective coatings, minimizing maintenance and lifecycle costs.

Exceptional Strength and Longevity

Weathering steel maintains its structural integrity over time, making it ideal for demanding load-bearing applications.

Eco-Friendly Choice

Eliminating chemical coatings and the need for frequent replacements makes weathering steel a sustainable option for environmentally conscious projects.

Distinctive Appearance

The rustic, weathered look enhances architectural projects, public art, and modern infrastructure.

Where Weathering Steel Delivers Value

Industries that require strong, corrosion-resistant materials depend on weathering steel for a variety of applications.

Bridges and Infrastructure

Engineers incorporate weathering steel in bridge construction because it withstands extreme weather with minimal maintenance needs. It is a reliable choice for highway overpasses, pedestrian walkways, and railway bridges.

Architectural and Structural Projects

Weathering steel enhances contemporary buildings with its durability and unique patina, making it a popular choice for facades, roofing, and decorative panels.

Transportation and Railcar

Freight cars, shipping containers, and truck trailers made from weathering steel resist damage from moisture, road salt, and industrial pollutants, extending their service life.

Energy and Industrial Equipment

Power plants, oil refineries, and industrial facilities use weathering steel to withstand environmental exposure while maintaining structural integrity over time.

Maximizing Performance with Weathering Steel

Weathering steel plates provide a powerful combination of durability, cost savings, and low maintenance. Self-protecting patina ensures long-term corrosion resistance, reducing upkeep while preserving structural strength. By integrating weathering steel into industrial, architectural, and infrastructure projects, engineers and designers can achieve both functional and aesthetic benefits without the ongoing expense of protective coatings or replacements by integrating weathering steel plates into applications across architectural, infrastructure, and transportation industry uses.

LEARN MORE: EXPLORE DIVERSE APPLICATIONS FOR STEEL PLATES

PRE-CUT AND PRE-TREATED STEEL PLATES: MAXIMIZING EFFICIENCY AND SAFETY

Steel beams of all sizes and specifications serve applications across industries, from commercial construction to infrastructure development, material handling, major manufacturing, and more. Westfield Steel serves the following sectors across many different applications and projects.

Infrastructure & Civil Engineering

Infrastructure and civil engineering projects, such as bridges, tunnels, and highways, require beams that can withstand heavy loads and provide long-term stability. Steel beams in this sector must handle significant stress while ensuring safety and durability for decades. The choice of beam type depends on the project’s specific demands, including load distribution and span length. The types of beams used in civil engineering include:

H-Beams: Extensively used for deep foundation support in bridges and tall structures, strengthening superstructures.

W-Beams: Commonly found in highways, tunnels, and bridges, W-beams offer excellent lateral support for large spans.

Box Beams (HSS): In modular construction and bridge support, HSS beams are lightweight yet strong, making them versatile for large-scale projects.

I-Beams: Essential in overpass construction and light rail systems, I-beams offer reliable lateral and vertical support.

Industrial & Manufacturing Facilities

Steel plates that arrive pre-cut and pre-treated offer significant advantages for manufacturers and construction teams. Instead of spending valuable time and resources cutting, shaping, and preparing steel on a busy job site or factory floor, you can receive production-ready materials already tailored to exact specifications. This approach streamlines operations, enhances workplace safety, and reduces material waste, ultimately leading to increased efficiency and cost savings.

Saving Time and Reducing Costs with Pre-Fabricated Steel Plates

When steel plates arrive at a job site or manufacturing facility ready for assembly or installation, production moves forward without unnecessary delays. Cutting, shaping, and treating steel in-house requires specialized equipment, highly trained personnel, and valuable time. By outsourcing these processes to an experienced and capable steel supplier, you can reallocate labor and resources to focus on core production tasks.

Critical production benefits of using pre-cut and pre-treated steel plates include:

Minimum Downtime

Eliminate on-site cutting and preparation, allowing projects to progress without interruptions through the delivery of materials that arrive production-ready.

Lower Labor Costs

Reduce the need for skilled labor dedicated to cutting and treating steel, freeing up personnel for other essential tasks.

Optimal Material Usage

Precision cutting and treating services reduce waste, ensuring efficient use of raw materials and minimizing excess scrap.

Enhancing Workplace Safety and Precision

Handling raw steel plates on a job site or factory floor presents inherent safety risks. Cutting steel generates sparks, heat, and airborne particles, increasing the chances of injuries and requiring strict safety protocols. Pre-cut and pre-treated steel plates help mitigate these risks by minimizing hazardous tasks in busy or uncontrolled environments. With fewer on-site cutting or fabrication responsibilities once your steel plates arrive, production managers and job site leaders significantly reduce the risk of workplace accidents.

Essential Specifications to Provide for Custom Steel Plate Processing

To maximize the benefits of pre-cut and pre-treated steel plates, customers must provide detailed specifications to their steel supplier and fabricator. Clearly communicating project requirements ensures the final steel plates meet expectations and integrate seamlessly into the production or construction process. Providing precise details in advance enables your supplier to deliver steel plates that align perfectly with project needs, saving time and ensuring a smooth production process. Some considerations include:

Plate Dimensions and Thickness

Specify exact measurements to ensure accurate cutting and minimal material waste.

Surface Treatment Requirements

Indicate whether plates need rust inhibitors, shot blasting, galvanizing, or other protective treatments to withstand outdoor elements or other demanding environments.

Edge Preparation Needs

Define beveling, chamfering, or other machining requirements to facilitate efficient welding, assembly, and installation.

Cutting Method Preferences

Choose between plasma, laser, or oxy-fuel cutting based on required precision, edge quality, and steel thickness.

Delivering Smarter Solutions with Pre-Cut and Pre-Treated Steel

Investing in pre-cut and pre-treated steel plates translates to streamlined operations, lower costs, and a safer work environment. By leveraging professional cutting and treatment services, you can prioritize productivity, reduce waste, and improve overall quality. Selecting the right steel plate specifications and partnering with a trusted supplier ensures projects proceed efficiently, meeting performance and budgetary goals.

LEARN MORE: CHOOSING THE RIGHT STEEL PLATE CUTTING METHOD