Custom Rebar Fabrication Supports Construction and Manufacturing Success

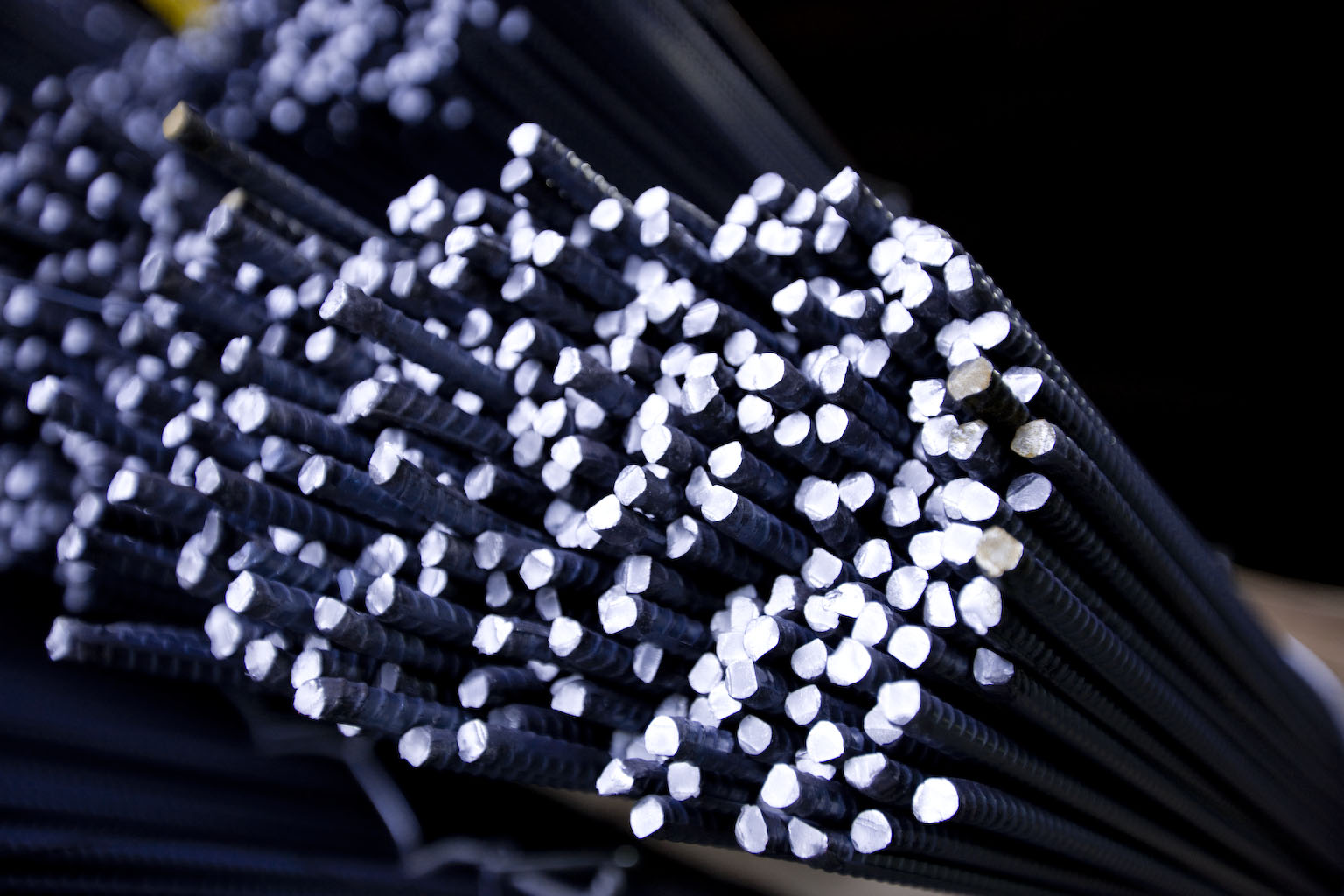

Material strength, precision, and quality help determine the success and performance of your construction and manufacturing projects. While it is often not a visible aspect of the project, steel rebar is a common and critical component in reinforced concrete structures. Rebar suppliers offering value-added custom rebar fabrication services can provide companies with considerable efficiency, cost savings, and project quality. Additionally, pre-production consulting and value-added services can significantly streamline construction and manufacturing operations.

What Can Rebar Fabrication Accomplish?

Rebar fabrication involves customizing steel reinforcing bars to meet your specific project requirements. Unlike standard rebar that comes in uniform lengths and diameters, capable steel suppliers can tailor fabricated rebar to meet a particular project’s unique dimensions, shapes, or other demands. Customization can include a combination of various value-added services, including:

- Cutting – Adjusting the length of rebar pieces to align with project specifications.

- Bending – Shaping rebar to fit architectural designs, unique contours, and structural needs.

- Welding – Joining rebar sections together for enhanced strength and stability.

- Coupling – Connecting rebar pieces using mechanical couplers for continuous reinforcement.

Top Five Benefits of Choosing a Steel Supplier with Custom Rebar Fabrication

Custom rebar fabrication provides many benefits, including the following top five.

- Precision and Quality Control:

Custom rebar fabrication ensures every piece of steel meets the exact specifications of your project. This accurate precision not only enhances the structural integrity of the construction but also reduces the likelihood of errors or a need to reorder. Rebar suppliers with fabrication services invest in advanced equipment and highly skilled labor to maintain exceptional quality standards, ensuring consistency and reliability in every piece of steel rebar. They typically follow stringent quality control measures, ensuring the rebar meets all industry standards and specifications. Moreover, respected suppliers ensure that their fabricated rebar complies with local building codes and industry regulations, reducing the risk of non-compliance issues and potential legal challenges.

- Time and Space Savings:

One of the most significant advantages of custom rebar fabrication from your steel supplier is reducing the time required to work with it on the project site. Construction teams can quickly and efficiently place and secure prefabricated rebar that arrives in ready-to-use condition. This rebar can be delivered just in time for installation, minimizing the need for extensive on-site storage. Choosing a supplier with rebar fabrication capabilities streamlines the construction process, helps meet tight deadlines, and can reduce the project timeline while reducing site clutter and potential safety hazards.

- Cost Efficiency

While custom-fabricated rebar may carry a higher upfront cost than standard-issue rebar, the overall cost savings can be substantial. Custom rebar minimizes off-cuts and leftover materials when manufactured to precise specifications, reducing on-site waste, which translates to direct cost savings. Prefabricated rebar also minimizes the need for highly skilled laborers who can accurately cut and bend them on-site, leading to lower labor costs as fewer specialized workers can complete the work.

- Enhanced Safety

Choosing prefabricated rebar enhances safety on construction sites by eliminating the need for on-site cutting, bending, and welding. This approach reduces exposure to various hazards and minimizes the risk of accidents and injuries. Additionally, a steel rebar supplier committed to quality controls and stringent safety protocols ensures that the prefabricated rebar is precise, defect-free, and safe to handle and install. The result is a safer, more efficient construction environment that protects workers and ensures the project’s structural integrity.

- Simplified Project Management

With custom fabrication, much of the complexity of handling the rebar transfers to the steel supplier. When project managers know they can count on a reliable provider to deliver rebar to their exact specifications, they can spend more time on other critical aspects of the construction process. Effective pre-production planning by your steel rebar supplier ensures deliveries include the right quantities and types of products on your schedule to avoid potential delays. Custom rebar fabrication also simplifies project management for you by consolidating supply chain logistics, resulting in more efficient coordination and communication and smoother project execution.

Westfield Steel Can Do More With Your Rebar

Choosing a steel rebar supplier that offers comprehensive fabrication services ensures you’ll receive materials meeting exact specifications, ultimately contributing to successful project outcomes. By focusing on these value-added services and their benefits, construction and manufacturing professionals can make informed decisions about their rebar suppliers to support better project outcomes.

Westfield Steel offers comprehensive, valued-added services, ensuring our clients and partners receive rebar tailored to their unique needs. Our commitment to quality, precision, and solving customers’ challenges helps save time and money while enhancing your projects’ safety, strength, and efficiency.

Are you looking to optimize your next construction or concrete-reinforcing project? Partnering with Westfield Steel can make all the difference. Our steel engineering experts have significant experience crafting custom rebar solutions and ensure you find suitable materials tailored to your needs, delivered on time and within budget. Talk to a steel expert at Westfield Steel today to help get your job done and standing strong.

Back