Precision for Every Project: Advanced Cutting and Fabrication Across Steel Angle Sizes

Achieving precision, strength, and versatility in every construction, manufacturing, or fabrication project starts with the right steel angle sizes. Whether your project or job site requires large or small steel angles, a steel supplier with advanced cutting and fabrication machinery ensures you receive steel angle components tailored perfectly to your needs. Across a wide range of steel angle dimensions and applications, Westfield Steel has the skills and tools to deliver unmatched light fabrication and cut-to-length capabilities.

The Sharpest Tools in the Steel Angle Shed

Peddinghaus Anglemaster 643 Q

The Peddinghaus Anglemaster 643 Q is a cornerstone of steel angle fabrication capabilities. As a full computer numerical control (CNC) angle line, this machinery brings precision and efficiency to the forefront of every project. It punches, shears, and marks steel angles simultaneously, reducing handling and ensuring each piece matches exact specifications. Processing steel angles up to 6″ x 6″ x 5/8″ with ease, the Anglemaster 643 Q eliminates bottlenecks and keeps production timelines on track.

One of the most powerful advantages of the Anglemaster 643 Q is its consistent accuracy, even during high-volume runs. Handling A36 steel angle sizes, ASTM A572 steel or other grades ensures uniformity throughout the batch. The ability to transition seamlessly between different steel angle dimensions adds flexibility and responsiveness to varied project demands.

The Anglemaster 643 Q’s high-speed operational capability supports larger projects and urgent deadlines without sacrificing cut quality. That speed gives steel suppliers like Westfield Steel and our customers a significant edge. The machine’s adaptability across steel grades and dimensions makes it a powerhouse for clients needing customized solutions. Whether a project demands standard steel angle sizes or uniquely specified profiles, the Anglemaster 643 Q delivers with precision.

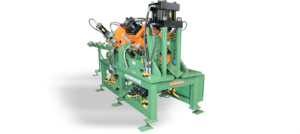

Geka Hydracrop 80 and Hydracrop 110

Our Geka Hydracrop 80 and Hydracrop 110 ironworkers strengthen Westfield Steel’s fabrication lineup with robust power and flexible processing. Dual-cylinder technology allows two operators to work independently at multiple stations, enhancing steel angle throughput while maintaining high precision standards.

These ironworkers bring massive punching force to the table—especially the Hydracrop 110, offering up to 110 tons of pressure. That strength makes creating clean, burr-free holes through even thick steel angles possible, ensuring perfect alignment and maximum strength in final assembly applications.

The machines’ ability to shear steel angles up to 152mm x 152mm x 13mm adds versatility for projects that push beyond standard steel angle sizes. With their flexible tooling configurations, the Geka Hydracrop units excel at creating consistent results across unique and varied steel angle dimensions. They play a key role in fulfilling industries’ dynamic steel angle requirements that demand both scale and precision.

Scotchman Ironworker DO 95/140-24M

Our Scotchman DO 95/140-24M steps up with exceptional results when speed and capacity are critical. Dual-operator functionality allows two fabrication experts to perform different tasks simultaneously without compromising quality, optimizing project flow.

Its steel angle punching, shearing, notching, and flat bar processing workstations make the DO 95/140-24M a true multi-tasking powerhouse. Operators waste no time switching tools or resetting equipment, keeping projects moving efficiently.

The Scotchman’s shearing capabilities stand out by producing clean, distortion-free cuts across a range of steel angle sizes. This precision ensures tight tolerances and stronger final assemblies in structural applications where every edge and hole matters. The Scotchman DO 95/140-24M supports diverse applications while maintaining the accuracy and speed that professional industries and steel customers demand.

Piranha P-50

Compact yet powerful, the Piranha P-50 ironworker handles smaller, intricate steel angle fabrication tasks without missing a beat. It’s ideal for projects that require customized components or quick-turnaround prototypes.

Despite its smaller footprint, the P-50 delivers 50 tons of punching and shearing force across a variety of steel angle sizes. It efficiently processes A36 steel angle sizes and other materials, making it a reliable machine for high-precision fabrication in limited workspace conditions.

The P-50’s multiple stations cover steel angle punching, shearing, and notching, enabling complete part processing on a single machine. With rapid setup and user-friendly controls, the P-50 minimizes downtime and maximizes output, particularly for specialty jobs.

The Piranha P50 allows for the same precision, excellence, and attention to detail on small-scale or specialty orders as Westfield Steel delivers on high-volume industrial projects.

Fabrication Versatility: Trust Westfield Steel to Make the Right Cut

Westfield Steel’s steel angle cutting, shearing, and punching equipment and services allow us to adapt to virtually any project requirement. Whether you need standard structural components or highly specialized parts, our team ensures every steel angle meets your design intent.

Our cut-to-length processing, precision punching, notching, and other custom fabrication capabilities extend across a wide range of steel grades and profiles, from basic steel angle to ASTM A572 high-strength, low-alloy options.

Westfield Steel is ready to deliver when your project depends on precise steel angles. Our cutting-edge machinery, including mechanical, hydraulic, and CNC solutions, ensures we can fabricate any steel angle size you need, from standard stock profiles to fully custom configurations.

Repeat customers trust Westfield Steel for our reliability, innovation, and commitment to excellence. Our steel experts work with you at every step, ensuring the finished products meet strength, dimensional, and performance requirements.

Contact Westfield Steel today to connect with a steel fabrication expert. Learn how our capabilities can support your success, or request a free, no-obligation quote for your next steel angle project.

Back