Steel Square Tube, Round, or Rectangular: Which is Right for You?

From broom handles and bike frames to vehicle chassis, structural building supports, and more, steel tubing is a staple in manufacturing and construction applications. Whether it is square, round, or rectangular, the shape of steel tubing contributes distinct strengths, limitations, and unique properties to make each style suitable for different purposes. Choosing the best steel square tube, rectangular tube, or round steel tube shape involves understanding the specific demands of your product or project’s application. Factors like load capacity, bending strength, strength-to-weight ratio, and ease of fabrication all play a role in the decision.

Square Tubing: Stability and Load-Bearing Strength

Square metal tubing is one of the most stable and load-bearing shapes available. With equal sides, steel square tubes distribute loads evenly across all four walls, making them exceptionally strong under compression.

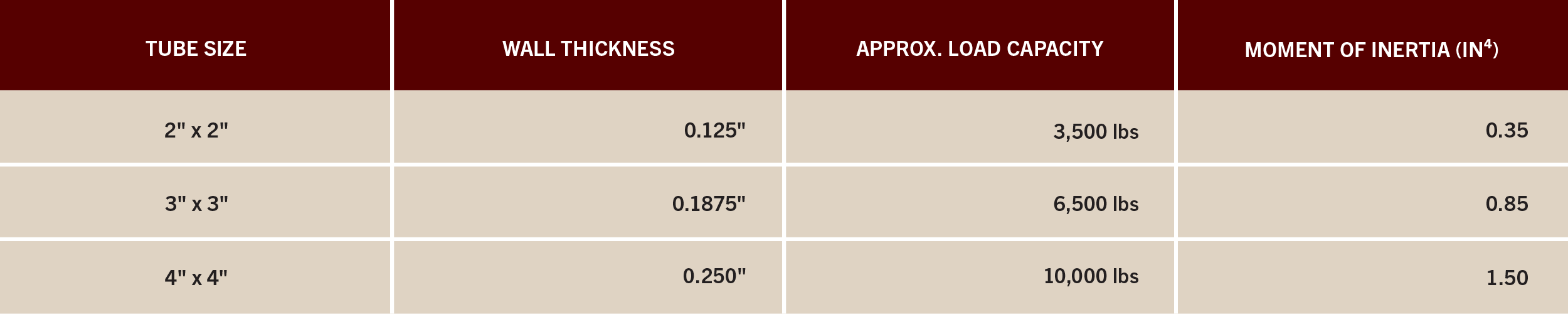

Strength and Rigidity

Many manufacturers value square tubing for its ability to bear heavy loads without buckling. Its high “moment of inertia,” means it is resistant to bending or warping when under pressure and is ideal for frameworks, load-bearing columns, and structural support beams. For example, a 2-inch square stainless steel tube with a 0.125-inch wall thickness can support thousands of pounds of vertical load without deformation.

Ideal Applications for Square Tubing

- Construction and Architecture: Construction crews rely on square tubing as support columns in buildings, bridges, and more due to its considerable load capacity.

- Shelving and Material Handling Racks: Square tubing provides a sturdy structure for storage systems, material conveyors, shelves, and racking units throughout manufacturing and production facilities.

- Machinery and Equipment Frames: Square tubing is the preferred shape for many machine frames, scaffolding, and heavy-duty racks, where stability and resilience are necessary.

Key Takeaway: Square steel tubing provides excellent support in applications requiring maximum stability and high load capacity, especially if a flat profile is essential to performance. The shape’s structure lends itself to securely welding or drilling through to attach hardware and other components.

Round Tubing: Superior for Torsion and Lightweight Needs

Round steel tubes are optimal for applications where strength and lightweight design must work together. Its unique symmetrical and circular shape offers distinct advantages, particularly in environments requiring torsional twisting strength or fluid motion.

Strength-to-Weight Ratio

Round tubing has a high strength-to-weight ratio, making it strong and relatively lightweight. For example, a 2-inch round steel tube with the same wall thickness as a comparable square tube still performs well under pressure but weighs approximately 20% less. This balance of strength and weight is ideal for aerospace and automotive applications, where reducing weight without compromising durability is crucial.

Torsional and Bending Strength

One of the main advantages of round tubing is its ability to handle twisting and torsional forces. The circular cross-section allows stress to distribute evenly along the entire tube’s wall. Its resistance to twisting makes round tubing automakers’ choice for applications such as axles, drive shafts, and other mechanical components where rotational movement and flexibility are necessary.

Ideal Applications for Round Tubing

- Automotive and Aerospace: Manufacturers frequently use round steel tubing in vehicle frames, roll cages, and structural support for lightweight frames.

- Handles and Railings: Its smooth, round shape and torsional strength make round tubing ideal for handlebars, handrails, and stair rails.

- Exhaust Systems and Pipes: In applications such as exhaust systems, the shape of round tubing allows it to handle pressure, torsion, and fluid flow efficiently.

Key Takeaway: Round tubing is best suited for projects involving rotation, torsion, and applications where weight reduction is critical. While it may not be as rigid under perpendicular loads, it provides optimal performance for dynamic or rotational applications. With no corners, round tubes are also easier to bend and shape in fabrication.

Rectangular Tubing: Directional Strength and Spatial Efficiency

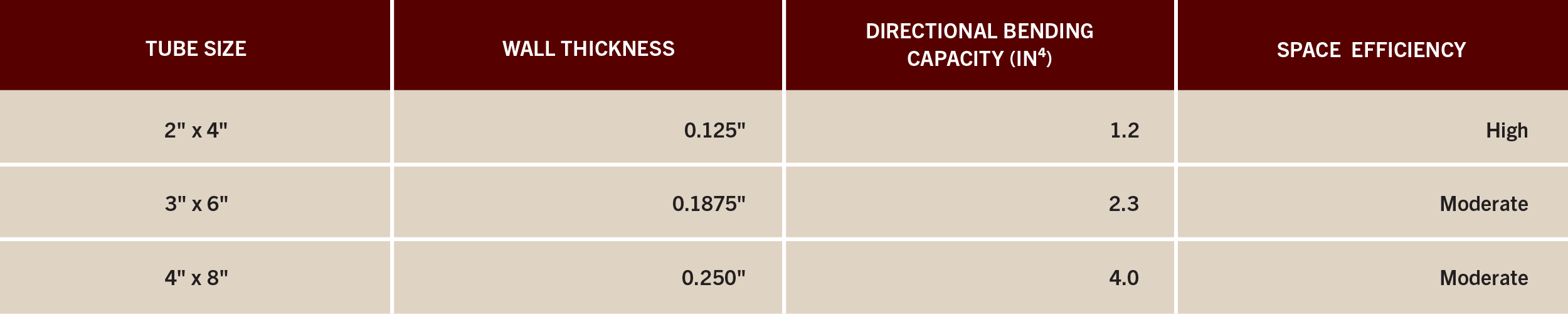

Rectangular tubing is a versatile option that offers specific benefits in projects requiring directional strength or space-saving design. With its longer cross-sectional dimensions, rectangular tubing is ideal for applications where the load is applied primarily in one direction.

Directional Strength

While rectangular tubing does not offer the same load-bearing capacity on all sides as square tubing, it provides higher bending resistance along its longer sides. This bending resistance makes rectangular tubing a practical choice for applications requiring high load strength along one axis, such as support beams and floor joists. For example, a 2×4 rectangular tube provides significant vertical support but may be less resistant horizontally.

Space Efficiency

The shape of rectangular tubing allows it to fit efficiently into tight corners or low-profile spaces. Within trailer beds, industrial shelving, or framework, rectangular tubes allow for compact designs in tightly confined spaces without sacrificing strength. Rectangular tubing is handy when a slim profile is advantageous, such as in furniture frames, HVAC equipment, or low-clearance structures.

Ideal Applications for Rectangular Tubing

- Trailer Beds and Truck Frames: Rectangular tubing provides significant directional strength, making it highly effective for flat, weight-bearing surfaces.

- Machinery and Equipment Shelving: Rectangular tubing is ideal for frames and shelving within machinery and equipment that must operate in compact spaces.

- Structural Support: Rectangular tubing offers efficient support and a sturdy framework in settings requiring resistance to bending and applying load strength in one direction.

Key Takeaway: Rectangular tubing’s directional strength and space efficiency make it an excellent choice for projects needing a slim profile or one-directional support. It is ideal for long, flat applications that may incorporate bolts or drilled holes but do not require the multi-directional load-bearing capacity of square tubing.

Talk to the Tube Experts at Westfield Steel

Selecting the right steel tubing shape is essential, and finding the right steel supplier is just as important. With a large inventory of structural, mechanical, and precision steel tubes across several steel grades, various inside and outside diameter sizes, wall thicknesses, and custom lengths, Westfield Steel can provide the exact steel tubing solutions for your needs.

We also offer a full range of value-added custom fabrication services to ensure your tubes arrive at your production facility or job site cut to spec, bent to fit, and ready to perform upon installation. By keeping all our logistics and delivery operations in-house through Westfield Steel Express, our customers depend on us for timely delivery where and when they need it. Reach out to the experts at Westfield Steel today to get your project started.

Back